Machines in our Factory

Haydraulic Swing Beam shear Model : HGL 3106 mm

HGL Hydraulic Swing Beam Shear is a very economical shear with

all of the features typically required.It has been imported directly from

Baykal Turkey. The pull down design provides the ability to have a low profile

hydraulic shear that is easy to operate by any operator. Shearing capacity is

1/4-inch and shearing length is 8, 10, 12 and 13 foot.

Technical Data

| Shearing Length | 3060 mm |

| Shearing angle (rake) | 1.6 degree |

| Strokes per minute | 20 cuts/min |

| Number of holddowns | 17 pcs |

| Backgauge range | 750 mm |

| Oil tank volume | 160 It |

| Main motor | 11kW |

| Backgauge motor | 0.37kW |

| Dimensions(LxWxH) | 3260x1320x1570 mm |

| Approx.Weight | 5.450 kgs |

Baykal APHS 31160 CNC Hydraulic Pressbrake

Baykal machine frames consist of a monolithic structure with hot rolled steel sheets of Fe 520 welded together. The two housings (shoulders) are obtained from the same sheet to ensure the same elasticity under stress. The ram and table are also obtained from Fe 520 steel sheets and are opportunely dimensioned to avoid deflection

The hydraulic cylinders are manufactured from high resistance steel incorporating chromium plated & ground rods.

Technical Data

| Press Length | 3100 mm |

| Press Force | 120 ton |

| Distance between frames | 2550 mm |

| Throat gap | 410 mm |

| Daylight Opening | 540 mm |

| Table width | 60 mm |

| Main motor | 11 kW |

| Oil tank volume | 140 It |

SFB 51 NC/C SERVO ROTATION NC CONT.PIPE BENDING MACHINE

- NC Control Unit

- 4 Hydraulic Pistons

- 100 Program Memory

- NC Carrier with Servo Motorized Rotation & Hydraulic Collet

- Flexible Mandrel

Technical Data:

| Maximum Capacity (mm) | Ø51x3mm |

| Maximum Bending Redious (mm) | 250 |

| Degree of bend | 190 |

| Hydraulic Pressure (bar) | 50-220 |

| Working length(mm) | 3000 |

| Bending speed(mm/s) | D/V |

| Motor Power(KW) | 8 |

| Machine Dimension(LxWxH) | 1200x4750x1300 |

| Weight(Kg) | 2600 |

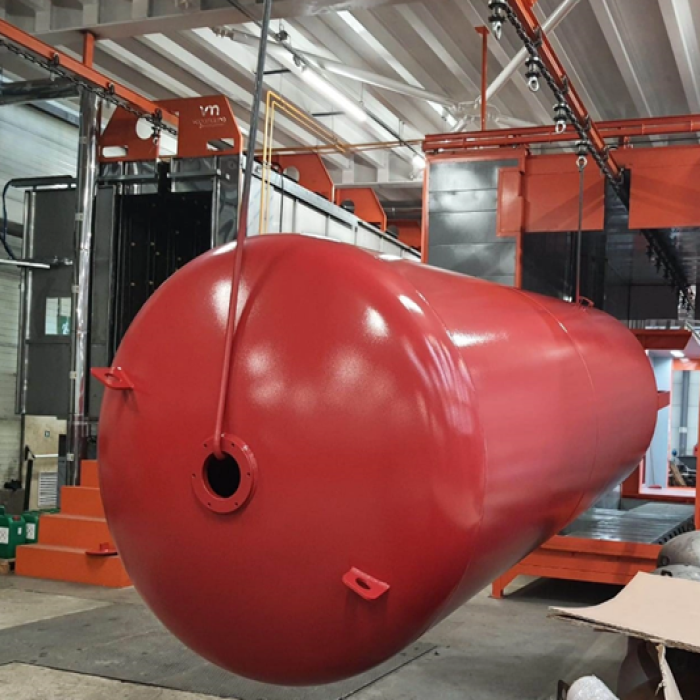

Powder coating plant

Powder coating is often applied electrostatically and then heated or exposed to ultraviolet radiation to cure, as opposed to traditional liquid paint, which is applied using an evaporating solvent. Thermoplastic or thermoset polymers could make up the powder. It is typically employed to produce a hard finish that is more durable than regular paint.

- It contains no solvents and release little or no amount of volatile organic compounds (VOC) into the atmosphere. Thus, there is no need for finishers to buy costly pollution control equipment.

- It can produce much thicker coatings than conventional liquid coatings without running or sagging.

- Curing time is significantly faster with powder coatings compared to liquid coatings